Features

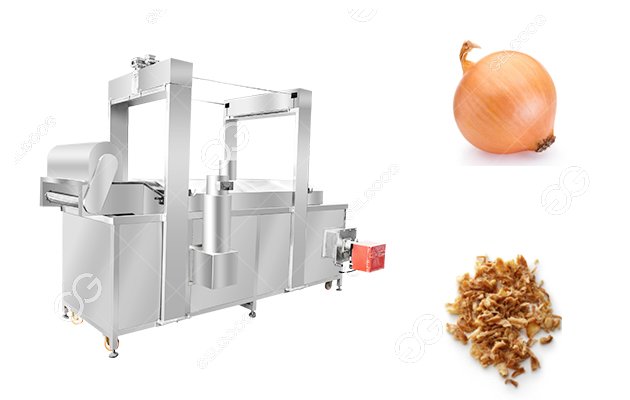

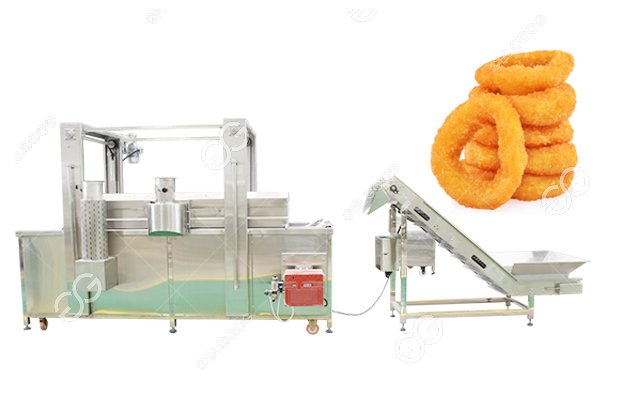

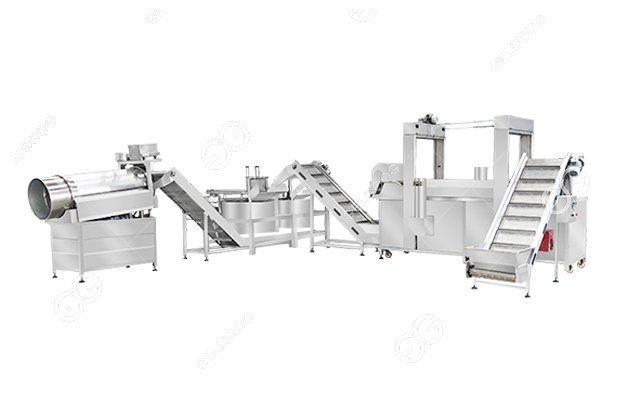

This fried onion rings processing machine is a continuous frying machine that uses precise temperature control to ensure that onion rings are fried evenly. In addition, you can deep-fry products with different temperature requirements, realize multiple functions in one machine, save production costs, and get more returns. This onion frying machine can also be used with onion frying production line, with high production efficiency, is an ideal fried onion making machine for commercial frying food. The finished products that can be obtained are: onion rings, onion chips, and fried onion chopped.

Composition Of Fried Onion Making Machine

This onion rings frying machine mainly includes frying upper cover, body, oil tank, heating system, feeding system, automatic slag removal system, temperature control system, oil storage tank, etc.

Composition Of Fried Onion Making Machine

This onion rings frying machine mainly includes frying upper cover, body, oil tank, heating system, feeding system, automatic slag removal system, temperature control system, oil storage tank, etc.

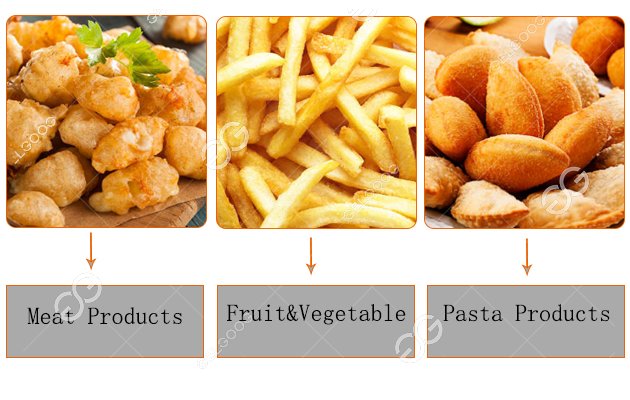

Application Of Fried Onion Rings Processing Machine

This onion frying machine has a wide range of applications and is often used in food processing. It can deep-fry a variety of products, including frying roots and vegetables, frying meat products, frying seafood, noodle products, and so on. With this machine, a variety of materials can be fried at the same time without odor.

Features Of Fried Onion Rings Processing Machine

- Touch screen control, convenient and fast, saving labor.

- The transmission system adopts frequency conversion speed regulation, which can be adjusted according to different product requirements.

- This onion frying machine adopts upper and lower double-layer mesh belts for conveying, and the product is sandwiched between the double-layer mesh belts to prevent the product from floating.

- The cover body and the conveying mechanism adopt a motor lifting mechanism, which is convenient for disassembly and cleaning.

- Automatic detection of oil level. When the oil level of the fried onion making machine is insufficient, it will automatically send out a signal and cut off the power to avoid interference.

- Optional equipment: automatic fire extinguishing system, oil storage tank, oil filter.

- The frying tank body is made of 5mm thick SUS304 plate, and the whole plate is formed by bending from top to bottom horizontally. There is no vertical welding seam at the bottom of the tank to avoid deformation or leakage at the bottom of the frying line due to excessive oil temperature.

- After the bottom of the frying line is scraped and discharged, the original counterparts are using the oil tank to connect the slag to the side conveying slag discharge system to avoid the fire of the frying line due to the use of the lower oil tank to connect the slag.

If you want to know more details about this fried onion making machine, you can leave us a message.

Technial Data

| Model |

Belt width (mm) |

oil pump power (kw) |

lifting power (kw) |

heating power |

Dimension (mm) |

| GGLZG3500A | 800 | 1.5 | 0.55 | 20Wkcal | 3700*1900*2400 |

| GGLZG5000A | 800 | 1.5 | 0.55*2 | 30Wkcal | 5200*1900*2400 |

| GGLZG6500A | 800 | 1.5 | 0.75*2 | 20Wkcal*2 | 6700*1900*2400 |

| GGLZG8000A | 800 | 2.2 | 0.75*2 | 30Wkcal*2 | 8200*1900*2400 |

| GGLZE3500A | 800 | 1.5 | 0.55 | 90KW | 3700*1600*2200 |

| GGLZE5000A | 800 | 1.5 | 0.55*2 | 120kw | 5200*1600*2200 |

| GGLZE6500A | 800 | 1.5 | 0.75*2 | 190kw | 6700*1600*2200 |

| GGLZE8000A | 800 | 2.2 | 0.75*2 | 255kw | 8200*1600*220 |

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com