Features

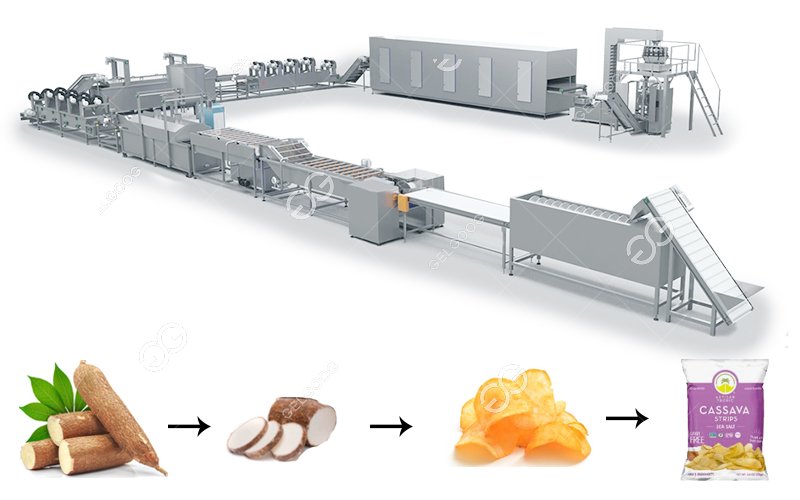

Cassava chips processing machine mainly includes washing machine, cutting machine, frying machine, seasoning machine, packaging machine. Cassava chips are becoming more and more popular and have great market prospects. We specialize in tapioca chips making machines and solutions that can help you start or expand your existing business.

Washing and peeling cassava---Cassava slicing---Blanching cassava slices ---Dewatering cassava slices---Frying cassava chips---Removing oil---Cassava chips seasoning---Cassava chips Package

1. Tapioca brush cleaning and peeling machine

The brush cleaning machine can clean cassava and has peeling effect, high cleaning degree, and can maintain the original color. Brushes can be customized.

√ The top is equipped with a clean water spray system, which can wash the waste and clean the hair roller in time, with high efficiency

√ The whole cassava chips making machine is made of stainless steel, and the rollers are supported at four points, which is easy to move.

√ Can be used for carrots, potatoes, potatoes, ginger, lotus root and other root fruits and vegetables.

√ A variety of brushes are available, which can be customized according to needs.

2. Cassava slicer Machine

Using the vertical feeding method, slices or strips can be customized according to the needs of the finished product, and the work efficiency is high.

√ The thickness of tapioca chips is adjustable.

√ Vertical feeding makes cassava chips round and neat.

√ Has high safety and security.

3. Cassava chips blanching machine

The blanching process can protect the color of the material for better flavor.

√ Tapioca chips keep good color and texture.

√ Inhibit the effect of mildew and prevent surface oxidation.

√ Adjustable blanching time and water temperature.

4. Cassava chips dehydrator

Need to remove water after blanching, easy to fry.

√ High dehydration efficiency.

√ The anti-vibration system runs smoothly.

√ Digital control cabinet automatic control.

The double mesh conveying method is adopted to ensure uniform frying, and the residue can be automatically filtered during the frying process to save fuel consumption.

√ Can be configured with oil storage tank and fine filter device.

√ A variety of heating methods can be freely selected: electric heating, gas heating.

√ Automatic discharge, frying time and frying temperature are controllable.

√ The mesh belt conveying is adjustable.

6. Cassava chips degreaser

Using the principle of vibration degreasing, and removing excess oil in fried cassava chips. Reduces greasiness.

√ High oil removal rate.

√ Can be recycled and reused to reduce costs.

7. Cassava chips seasoning machine

The degreasing tapioca chips can be mixed with various seasonings to make finished products with various flavors.

√ Automatic spreading and adjustable speed.

√ Low breakage rate in seasoning process.

√ Suitable for any fried food.

8. Cassava Chips Packaging Machine

The use of nitrogen to protect fried cassava chips from reacting with oxygen extends the shelf life.

√ Sealing, cooling, nitrogen filling, and coding (optional) are completed at one time.

√ Tightly sealed for easy storage.

500kg/h Cassava Chips Production Process

Washing and peeling cassava---Cassava slicing---Blanching cassava slices ---Dewatering cassava slices---Frying cassava chips---Removing oil---Cassava chips seasoning---Cassava chips Package

Introduction Of Cassava Chips Processing Machine

1. Tapioca brush cleaning and peeling machine

The brush cleaning machine can clean cassava and has peeling effect, high cleaning degree, and can maintain the original color. Brushes can be customized.

√ The top is equipped with a clean water spray system, which can wash the waste and clean the hair roller in time, with high efficiency

√ The whole cassava chips making machine is made of stainless steel, and the rollers are supported at four points, which is easy to move.

√ Can be used for carrots, potatoes, potatoes, ginger, lotus root and other root fruits and vegetables.

√ A variety of brushes are available, which can be customized according to needs.

2. Cassava slicer Machine

Using the vertical feeding method, slices or strips can be customized according to the needs of the finished product, and the work efficiency is high.

√ The thickness of tapioca chips is adjustable.

√ Vertical feeding makes cassava chips round and neat.

√ Has high safety and security.

3. Cassava chips blanching machine

The blanching process can protect the color of the material for better flavor.

√ Tapioca chips keep good color and texture.

√ Inhibit the effect of mildew and prevent surface oxidation.

√ Adjustable blanching time and water temperature.

4. Cassava chips dehydrator

Need to remove water after blanching, easy to fry.

√ High dehydration efficiency.

√ The anti-vibration system runs smoothly.

√ Digital control cabinet automatic control.

5. Cassava Chip Fryer Machine

The double mesh conveying method is adopted to ensure uniform frying, and the residue can be automatically filtered during the frying process to save fuel consumption.

√ Can be configured with oil storage tank and fine filter device.

√ A variety of heating methods can be freely selected: electric heating, gas heating.

√ Automatic discharge, frying time and frying temperature are controllable.

√ The mesh belt conveying is adjustable.

6. Cassava chips degreaser

Using the principle of vibration degreasing, and removing excess oil in fried cassava chips. Reduces greasiness.

√ High oil removal rate.

√ Can be recycled and reused to reduce costs.

7. Cassava chips seasoning machine

The degreasing tapioca chips can be mixed with various seasonings to make finished products with various flavors.

√ Automatic spreading and adjustable speed.

√ Low breakage rate in seasoning process.

√ Suitable for any fried food.

8. Cassava Chips Packaging Machine

The use of nitrogen to protect fried cassava chips from reacting with oxygen extends the shelf life.

√ Sealing, cooling, nitrogen filling, and coding (optional) are completed at one time.

√ Tightly sealed for easy storage.

Advantages Of Tapioca Chip Making Machine

- Support customization: each machine can be customized, or customized cassava chips processing solutions for customers.

- Simple operation: most machines are controlled by intelligent operation panel, which is convenient to operate.

- High quality: The cassava chip making machines provided by our company are all made of stainless steel materials that meet food safety.

- Easy to maintain and clean: It is convenient to clean and maintain the machine after the work is over.

- Wide application: can process all kinds of fruits and vegetables, especially root fruits and vegetables.

Technial Data

| No. | Name | Power | Dimension(mm) | Output(kg/h) |

| 1 | Cassava Cleaner Peeler | 1.5kw | 1600*730*840 | 800 |

| 2 | Cassava Cutting Machine | 1.1kw | 950*900*1000 | 700 |

| 3 | Blanching Machine | 24kw | 1000*500*800 | 500 |

| 4 | Centrifugal Dehydrator | 1.5kw | 1000*500*850 | 500 |

| 5 | Cassava Chips Frying Machine | 36kw | 500*500*900 | 100 |

| 6 | Deoiling machine | 1.5kw | 1000*600*850 | 700 |

| 7 | Flavoring machine | 1.1kw | 1100*800*1300 |

600 |

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com