Features

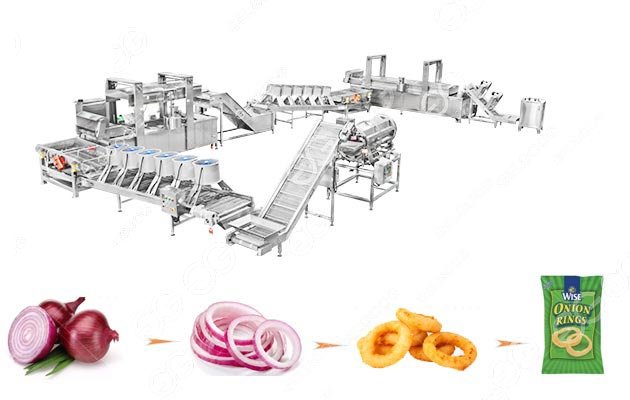

The full-automatic fried onion production line is mainly composed of root cutter, peeler, washing machine, ring cutter, hoist, fryer, air dryer, quick-freezer, packaging machine and other equipment. The ratio of raw materials to finished products in the production process is 4:1. The hourly production capacity is 200-1000kg/h. In addition, we specialize in providing customers with fried onions (onion rings, onions) solutions, welcome to customize!

Fried Onion Manufacturing Process

Advantages Of Fried Onion Production Line

Fried Onion Manufacturing Process

- Onion root cutting machine: automatic root cutting, one-time automatic cutting clean, no damage, can achieve perfect root cutting. higher efficiency.

- Onion peeling machine: I use a chain peeling machine to peel the onions, and separate the onion skins with air-compressed airflow, and peeling continuously while traveling. The machine has the characteristics of high removal rate, no damage to onions, and high peeling efficiency.

- Onion cleaning machine: Use the bubble shock wave principle to rinse the surface of vegetables and fruits, and effectively avoid the damage of the material during the cleaning process. It has the characteristics of saving water, electricity, time, labor, and sanitation.

- Onion ring cutting machine: The onion ring cutting machine is easy to operate and has high output. The thickness of the slice can be adjusted at will, and the cutting angle can be customized. The cut circle piece has a smooth surface and no breakage.

- Onion fry machine: The continuous frying machine is used for frying, which can realize continuous frying of onion rings. The conveyor belt of the onion fryer conveys the onion rings for frying and discharging. This onion fry machine can not only realize automatic frying, but also has many functions such as scraping residue, automatic lifting, oil circulation and so on.

- Onion de-oiling machine: adopts centrifugal de-oiling machine, which occupies a small area, low energy consumption, convenient operation, time-saving and labor-saving, quick and uniform mixing effect, and convenient feeding.

- Onion seasoning machine: adopts a drum-type seasoning machine, made of stainless steel, reasonable structure, safe and hygienic, durable, no noise, high efficiency, widely used in a variety of fried products. The length and diameter of the seasoning cylinder can be customized according to customer needs.

- Onion packaging machine: Onion ring food packaging machine equipment has high measurement and detection accuracy, fast efficiency, raw material saving and can reduce labor costs.

- Onion Quick Freezer: Extend the shelf life.

Advantages Of Fried Onion Production Line

- The operation is simple, safe, easy to clean, easy to maintain, and save fuel consumption.

- High scalability, can design an assembly line that meets the production requirements of the product according to the needs of the factory;

- Save factory production cost, high degree of automation, low initial investment, high rate of return.

Technial Data

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com