Features

The introduction of semi automatic french fries production line:

This semi-automatic french fries production line is suitable for small scale french fries manufacturers. The production line provides different output options, such as 50 kg/h,100 kg/h, 150 kg/h and more.The output of the machine can be customized according to the needs of customers.The French fries production line is widely used in restaurants, hotels, canteens, a few days processing plants.The semi-automatic French fries production line is not standard customized, according to the specific needs of users, professional customized machine functions, specifications,etc.The production line can also be used to produce potato chips.We also supply fully automatic and large scale french fries production line.

The features of semi-automatic french fries production line:

1. Equipment operation is simple and convenient, efficient production, safety and health.

2. The equipment has reasonable design, stable structure, simple and convenient cleaning, small investment and quick return.

3.The french fries production line can realize automatic production and save a lot of labor cost compared with manual production.

4. The equipment is made of SUS304 stainless steel,which is strong and durable, long service life, good corrosion resistance.

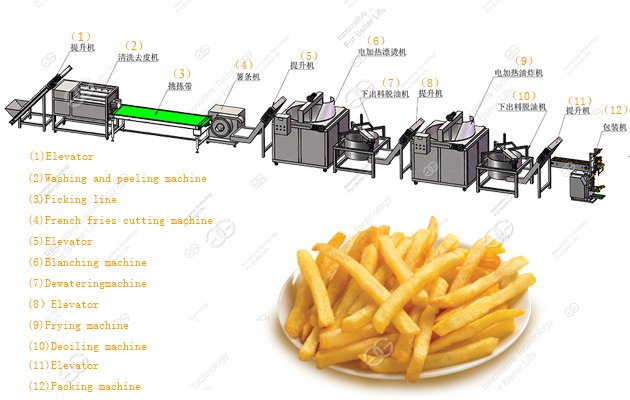

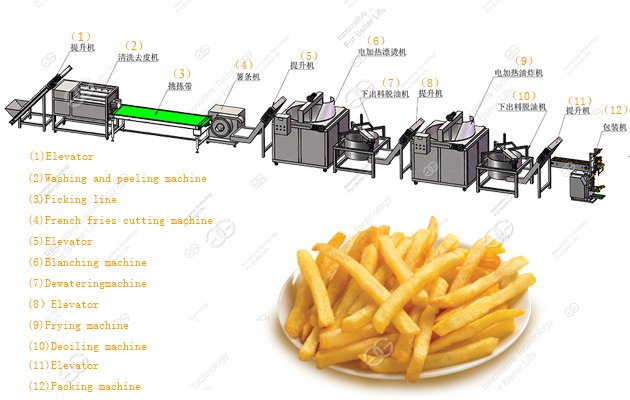

Semi-automatic french fries production line process flow:

Lifting feed--cleaning and peeling--selection and pruning--lifting feed--cutting--blanching color protection--dehydration--frying--deoiling--seasoning--packaging.

Introdution of main machine:

Potato washing and peeling machine:Brush type cleaning and peeling machine with high quality brush stick can complete cleaning and peeling work at the same time.High efficiency and low loss.

French fries cutting machine:It not only can cut potatoes into strips,also can cut into slices.Slice thickness and strip size can be adjusted at will。

Blanching machine:Rinse and color protect the strips (chips).

Dewatering machine:Centrifugal dewatering is adopted.Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips.Improve production efficiency and reduce production cost.

Frying machine:This equipment is advanced oil - water mixing frying equipment.Because the proportion of water and oil is different, the water is below, the oil is heated in the upper layer and fried french fries, the residue produced is directly precipitated in the water, the oil does not emit black smoke, greatly extending the service cycle of the oil, so that the cost is greatly reduced.Oil temperature control, thus ensuring the quality and taste of potato chips.When the work is done, the water is released and the residue flows out with the water.

Deoiling machine:The machine will be freshly Fried potato chips (strips) for deoiling, to overcome the potato chips (strips) high oil content, greasy mouth defects.Enhances the texture of potato chips (chips).

Seasoning machine:Drum seasoning machine is made of stainless steel.Potato chips (strips) are evenly turned in the rotation of the roller, and seasoning is added by sprinkling type or spray type.Seasoning evenly and not easily broken.

Packing machine:When packaging, fill the bag with nitrogen gas, which can effectively prevent chips (strips) from being broken and extend the shelf life.Inflation, packaging, coding a complete.

After-sales service

1. One-year warranty: within one year, our company will be responsible for the maintenance of machine failure.

2. Lifetime warranty: after the warranty period, at any time of machine failure, the manufacturer will provide spare parts at cost price to guide maintenance.At any time, you can buy the accessories you need in our factory.

3. One-to-one after-sales service is adopted. If you have any problems in operation, please consult in time.

The video of semi automatic french fries production line :

This semi-automatic french fries production line is suitable for small scale french fries manufacturers. The production line provides different output options, such as 50 kg/h,100 kg/h, 150 kg/h and more.The output of the machine can be customized according to the needs of customers.The French fries production line is widely used in restaurants, hotels, canteens, a few days processing plants.The semi-automatic French fries production line is not standard customized, according to the specific needs of users, professional customized machine functions, specifications,etc.The production line can also be used to produce potato chips.We also supply fully automatic and large scale french fries production line.

The features of semi-automatic french fries production line:

1. Equipment operation is simple and convenient, efficient production, safety and health.

2. The equipment has reasonable design, stable structure, simple and convenient cleaning, small investment and quick return.

3.The french fries production line can realize automatic production and save a lot of labor cost compared with manual production.

4. The equipment is made of SUS304 stainless steel,which is strong and durable, long service life, good corrosion resistance.

Semi-automatic french fries production line process flow:

Lifting feed--cleaning and peeling--selection and pruning--lifting feed--cutting--blanching color protection--dehydration--frying--deoiling--seasoning--packaging.

Introdution of main machine:

Potato washing and peeling machine:Brush type cleaning and peeling machine with high quality brush stick can complete cleaning and peeling work at the same time.High efficiency and low loss.

French fries cutting machine:It not only can cut potatoes into strips,also can cut into slices.Slice thickness and strip size can be adjusted at will。

Blanching machine:Rinse and color protect the strips (chips).

Dewatering machine:Centrifugal dewatering is adopted.Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips.Improve production efficiency and reduce production cost.

Frying machine:This equipment is advanced oil - water mixing frying equipment.Because the proportion of water and oil is different, the water is below, the oil is heated in the upper layer and fried french fries, the residue produced is directly precipitated in the water, the oil does not emit black smoke, greatly extending the service cycle of the oil, so that the cost is greatly reduced.Oil temperature control, thus ensuring the quality and taste of potato chips.When the work is done, the water is released and the residue flows out with the water.

Deoiling machine:The machine will be freshly Fried potato chips (strips) for deoiling, to overcome the potato chips (strips) high oil content, greasy mouth defects.Enhances the texture of potato chips (chips).

Seasoning machine:Drum seasoning machine is made of stainless steel.Potato chips (strips) are evenly turned in the rotation of the roller, and seasoning is added by sprinkling type or spray type.Seasoning evenly and not easily broken.

Packing machine:When packaging, fill the bag with nitrogen gas, which can effectively prevent chips (strips) from being broken and extend the shelf life.Inflation, packaging, coding a complete.

After-sales service

1. One-year warranty: within one year, our company will be responsible for the maintenance of machine failure.

2. Lifetime warranty: after the warranty period, at any time of machine failure, the manufacturer will provide spare parts at cost price to guide maintenance.At any time, you can buy the accessories you need in our factory.

3. One-to-one after-sales service is adopted. If you have any problems in operation, please consult in time.

The video of semi automatic french fries production line :

Technial Data

| No. | Name | Power | Dimension(mm) | Output(kg/h) |

| 1 | Potato Cleaner Peeler | 1.5kw | 1600*730*840 | 800 |

| 2 | Potato Cutting Machine | 1.1kw | 950*900*1000 | 700 |

| 3 | Blanching Machine | 24kw | 1000*500*800 | 500 |

| 4 | Centrifugal Dehydrator | 1.5kw | 1000*500*850 | 500 |

| 5 | French Fries Fryer | 36kw | 500*500*900 | 100 |

| 6 | Deoiling machine | 1.5kw | 1000*600*850 | 700 |

| 7 | Flavoring machine | 1.1kw | 1100*800*1300 | 600 |

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com