What Is The Cost of French Fries Production Line

Mar 15, 2024 | Emily

124

124

124

124

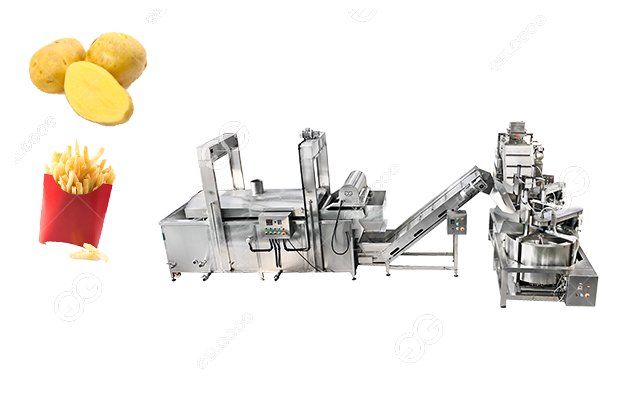

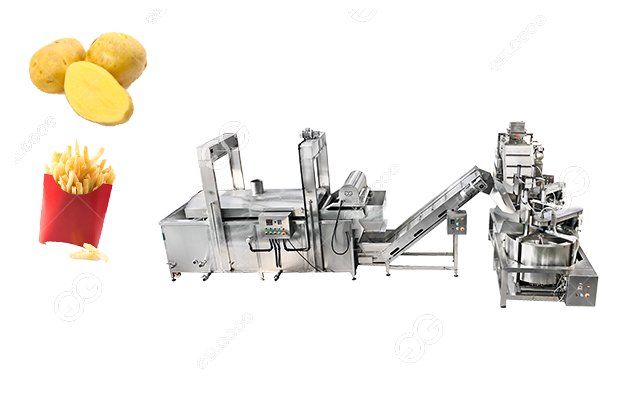

French fries, beloved by millions around the globe, are a staple in the fast-food industry and household kitchens alike. The crispy, golden strips of potato goodness owe their widespread availability to efficient french fries production lines that streamline the process from potato to plate. But what exactly determines the cost of these production lines? Let's delve into the factors influencing cost of french fries production line.

Factors influencing cost:

Capacity and output: The production capacity of a french fries production line plays a significant role in determining its cost. Lines with higher output capabilities typically come with a heftier price tag due to the advanced machinery and technology required to meet the demand.

Automation level: Automation can significantly enhance efficiency and reduce labor costs. Production lines with higher levels of automation, such as those equipped with robotic systems for sorting, cutting, and packaging, tend to be more expensive upfront but can yield long-term savings in operational expenses.

Customization and flexibility: Some production lines offer modular designs that allow for customization based on specific requirements. The ability to adapt to different potato varieties, cut sizes, and packaging options may come at an additional cost but provides versatility in production.

Quality and technology: Cutting-edge technology and high-quality materials contribute to the reliability and performance of a production line. Advanced features like precise cutting mechanisms, oil filtration systems, and quality control sensors ensure consistent product quality but may elevate the overall cost.

Energy efficiency: Energy-efficient equipment not only reduces operational costs but also aligns with sustainability goals. Production lines equipped with energy-saving components or renewable energy systems may have a higher initial investment but offer long-term benefits in terms of cost savings and environmental stewardship.

After-sales support and maintenance: Comprehensive after-sales support, including installation, training, and maintenance services, can add to the total cost of a production line. However, reliable technical assistance and prompt spare parts availability are crucial for minimizing downtime and maximizing productivity.

Equipment included in a typical production line:

Potato washing and peeling machine: This equipment cleans and removes the outer skin of potatoes, preparing them for the next processing steps.

Cutting machine: A cutting machine slices the peeled potatoes into uniform strips or shapes, ensuring consistency in size and appearance.

Blanching equipment: Blanching machines briefly immerse the potato strips in hot water or steam to soften them, facilitate moisture removal, and preserve color.

Drying system: Drying systems remove excess moisture from the blanched potatoes, preparing them for frying and enhancing the crispiness of the final product.

Frying equipment: Continuous fryers cook the potato strips in hot oil to achieve the desired texture and flavor. These fryers may feature temperature control, oil filtration, and conveyor systems for efficient operation.

Seasoning and packaging machinery: After frying, the french fries can be seasoned with various flavors before being automatically weighed, sorted, and packaged for distribution.

Cost range:

The cost of a french fries production line can vary widely depending on the factors mentioned above. Entry-level systems designed for small-scale operations may start from tens of thousands of dollars, while high-capacity, fully automated lines with advanced technology can exceed several million dollars.

The cost of a french fries production line is influenced by factors such as capacity, automation level, customization, quality, energy efficiency, and after-sales support. While the initial investment may seem substantial, a well-designed and properly maintained production line can yield significant returns in terms of efficiency, consistency, and product quality over its lifespan.

Factors influencing cost:

Capacity and output: The production capacity of a french fries production line plays a significant role in determining its cost. Lines with higher output capabilities typically come with a heftier price tag due to the advanced machinery and technology required to meet the demand.

Automation level: Automation can significantly enhance efficiency and reduce labor costs. Production lines with higher levels of automation, such as those equipped with robotic systems for sorting, cutting, and packaging, tend to be more expensive upfront but can yield long-term savings in operational expenses.

Customization and flexibility: Some production lines offer modular designs that allow for customization based on specific requirements. The ability to adapt to different potato varieties, cut sizes, and packaging options may come at an additional cost but provides versatility in production.

Quality and technology: Cutting-edge technology and high-quality materials contribute to the reliability and performance of a production line. Advanced features like precise cutting mechanisms, oil filtration systems, and quality control sensors ensure consistent product quality but may elevate the overall cost.

Energy efficiency: Energy-efficient equipment not only reduces operational costs but also aligns with sustainability goals. Production lines equipped with energy-saving components or renewable energy systems may have a higher initial investment but offer long-term benefits in terms of cost savings and environmental stewardship.

After-sales support and maintenance: Comprehensive after-sales support, including installation, training, and maintenance services, can add to the total cost of a production line. However, reliable technical assistance and prompt spare parts availability are crucial for minimizing downtime and maximizing productivity.

Equipment included in a typical production line:

Potato washing and peeling machine: This equipment cleans and removes the outer skin of potatoes, preparing them for the next processing steps.

Cutting machine: A cutting machine slices the peeled potatoes into uniform strips or shapes, ensuring consistency in size and appearance.

Blanching equipment: Blanching machines briefly immerse the potato strips in hot water or steam to soften them, facilitate moisture removal, and preserve color.

Drying system: Drying systems remove excess moisture from the blanched potatoes, preparing them for frying and enhancing the crispiness of the final product.

Frying equipment: Continuous fryers cook the potato strips in hot oil to achieve the desired texture and flavor. These fryers may feature temperature control, oil filtration, and conveyor systems for efficient operation.

Seasoning and packaging machinery: After frying, the french fries can be seasoned with various flavors before being automatically weighed, sorted, and packaged for distribution.

Cost range:

The cost of a french fries production line can vary widely depending on the factors mentioned above. Entry-level systems designed for small-scale operations may start from tens of thousands of dollars, while high-capacity, fully automated lines with advanced technology can exceed several million dollars.

The cost of a french fries production line is influenced by factors such as capacity, automation level, customization, quality, energy efficiency, and after-sales support. While the initial investment may seem substantial, a well-designed and properly maintained production line can yield significant returns in terms of efficiency, consistency, and product quality over its lifespan.

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com