Features

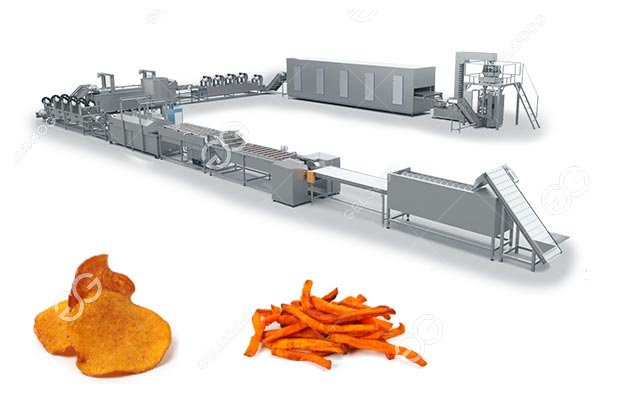

The sweet potato frying machine solution provided by our company can automatically realize the process from raw materials to finished products, and has the characteristics of high production efficiency and labor cost saving. Sweet potatoes are rich in nutritional value and are usually processed into sweet potato chips and sweet potato strips-popular fried snacks,which have great market prospects.

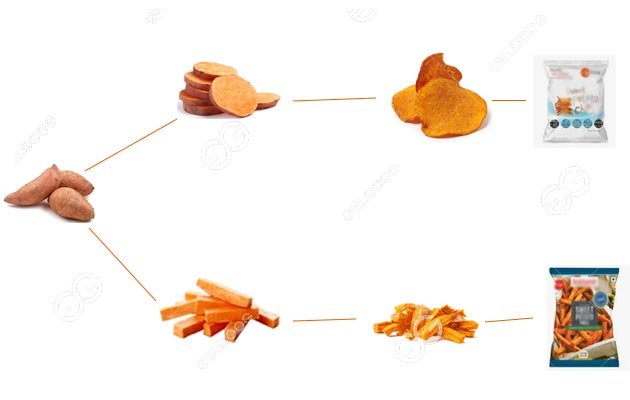

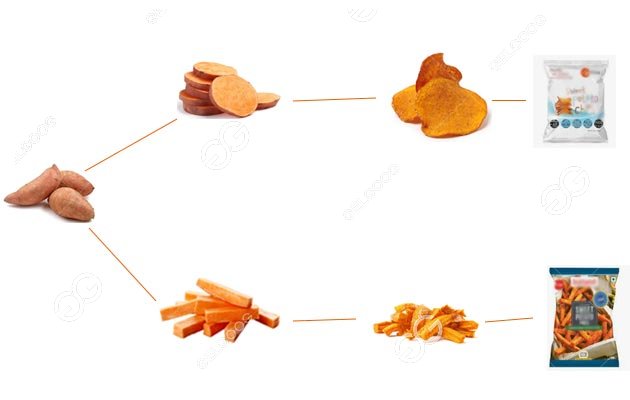

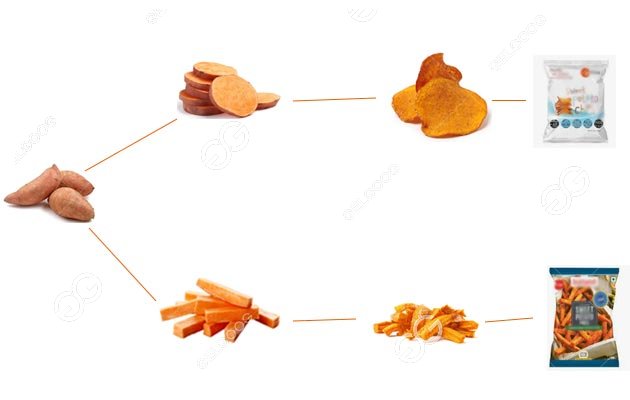

Ingredients: sweet potato

Finished product: sweet potato chips, sweet potato strips

Output: 200-1000kg/h, can be customized

Processing technology: sweet potato - cleaning and peeling - cutting - blanching - removing water - frying - degreasing - seasoning - packaging

Process Of Sweet Potato Chips And Sweet Potato Fries Production Line

Advantages Of The Production Line

Ingredients: sweet potato

Finished product: sweet potato chips, sweet potato strips

Output: 200-1000kg/h, can be customized

Processing technology: sweet potato - cleaning and peeling - cutting - blanching - removing water - frying - degreasing - seasoning - packaging

Process Of Sweet Potato Chips And Sweet Potato Fries Production Line

- Sweet potato selection: Choose a sweet potato that is fuller and has a smooth and clean surface.

- Sweet potato Washing and peeling: Clean the sweet potato and remove the skin of the sweet potato in the brush washing machine. What we provide is a washing and peeling integrated machine, which is efficient and water-saving.

- sweet potato slicer machine: According to the finished product, it can be cut into sweet potato chips and sweet potato fries, and the size can be adjusted.

- Blanching: Use a continuous blanching machine to blanch the sweet potato chips or sweet potato strips to achieve the purpose of color protection.

- Dewatering: There will be moisture on the surface of the blanched material, which needs to be removed to reduce the frying time.

- Sweet potato chips frying machine(sweet potato fries fryer machine): The sweet potato chips or sweet potato fries are deep-fried using a frying machine with a continuous temperature adjustable. After frying, the color of the finished product is beautiful, the taste is crisp, and the quality is high.

- De-oiling: The finished product after frying is usually de-oiled with a de-oiling machine to reduce the greasy feeling.

- Seasoning machine: The drum seasoning machine is used to evenly season the fried materials, and the flavor of the finished product after seasoning is excellent.

- Packing machine: The finished product is packed by a ten-head weighing machine.

Advantages Of The Production Line

- Reduce labor and increase productivity.

- Integrate production technology, the production line can be deployed according to production needs.

- Save factory production costs and shorten the working week.

- The quality of the product obtained is good.

Technial Data

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com