Features

The introduction of potato chips production line:

The fully automatic potato chips production line is used to process raw potates into taste potato chips with high efficiency.It is suitable for large scale potato chips makers.The production line has different output options, 300 kg/h, 500 kg/h, 1000 kg/h and more.The production line can be customized according to the needs of customers, different output, the price will be different.The potato chips production line is high automation, high production efficiency, energy saving, greatly reduce production costs.The production line is widely used in canteens, hotels, restaurants, catering companies, supermarkets, food processing companies and so on.It also can used to produce french fries.We also supplky small scale potato chips production line.

The features of potato chips production line:

1. The potato chips production line operation is simple, high degree of automation, no need for special operation, reduce labor costs.

2. The fully automatic potato chips production line has stable performance, long service life and low failure rate in the production process.

3. The production line saves oil and environmental protection, has high production efficiency, improves the market competition ability for the customer, has increased the profit space.

4. The potato chips production line is made of high quality stainless steel,safer and more hygienic production

5. The production line has large output and can be customized according to the needs of customers.

6. The thickness of potato chips can be adjusted or customized according to the special needs of customers.

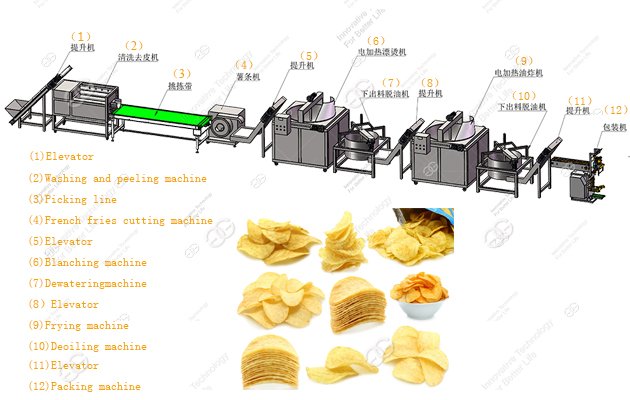

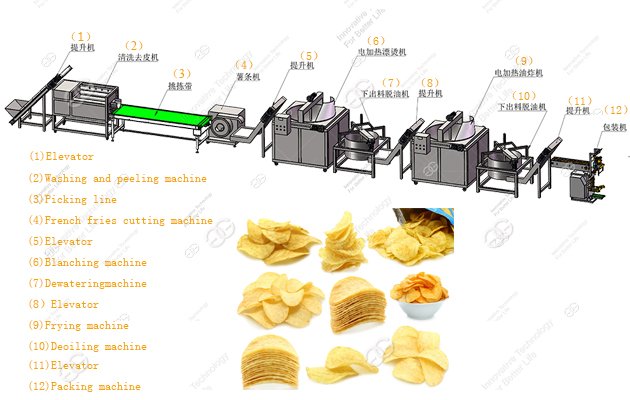

Work flow of potato chips production line:

Lifting feed--washing and peeling--selection and pruning--lifting feed--cutting--blanching color protection--dehydration--frying--deoiling--seasoning--packaging.

Main machine of potato chips production line:

Washing and peeling machine:It can peel potatoes in a short time and has a low rate of breakage.The machine can be continuously peeled and cleaned.It saves water and no pollution than manual production.

Potato Chips Cutting machine:The machine is made of food grade stainless steel.With a different knife, the potatoes can be cut into strips and slices.Place the peeled potatoes or sweet potatoes in the top feeder.The finished slices are then drained on one side of the machine.The machine has high efficiency and excellent performance.The production of the whole machine conforms to the sanitary requirements.

Blanching machine:The machine is equipped with temperature control panel and heating timer.The machine needs to be filled with water.Turn on the switch and the water will heat up quickly.Place the potato chips in the machine and the machine begins to blanch.Blanching makes it easy to fry potatoes, saving more oil and electricity.Finished French fries or potato chips will also be beautiful in color and taste the best.

Dewatering machine:Before frying, remove the surface water from the hot stamped potato chips to save grease and avoid oil splashing.When the potato chips or french fries are put into the machine ,and turned on the machine, the machine will work at high speed and complete the dehydration process in a short time.

Frying machine:Made of food grade stainless steel.It consists of frying pan, electric heat pipe, control panel, motor and so on.Heating temperature and frying time can be adjusted according to your requirements.In addition, the machine adopts advanced technology to save oil and keep the taste and color of food.

Deoiling machine:Similar to the dehydrator, the machine is also made of food grade stainless steel.After frying, the finished fries or fries need to be de-oiled.This way, you won't get greasy eating chips or chips.Recycled oil can be reused to reduce production costs.

Seasoning machine:The roller mixing machine adopts the rotary drum, which is equipped with mixing plate to ensure the uniformity of the taste.

Precautions for use:

1. The machine should be placed in a stable place. The machine with wheels should lock the casters.

2. Please make sure that there is no foreign matter stuck in the material mouth of the machine. Please connect the power supply and ground wire according to the power supply instructions on the label.

3. Do not put your hands into the machine when the machine is in operation.

4. After using the machine, please be sure to cut off the power supply before cleaning the machine5. The circuit part cannot be cleaned. Please pay attention to sharp parts such as cutting tools when cleaning.

The fully automatic potato chips production line is used to process raw potates into taste potato chips with high efficiency.It is suitable for large scale potato chips makers.The production line has different output options, 300 kg/h, 500 kg/h, 1000 kg/h and more.The production line can be customized according to the needs of customers, different output, the price will be different.The potato chips production line is high automation, high production efficiency, energy saving, greatly reduce production costs.The production line is widely used in canteens, hotels, restaurants, catering companies, supermarkets, food processing companies and so on.It also can used to produce french fries.We also supplky small scale potato chips production line.

This is our potato chips production have sold to Pakistan, and help customer to set and run machine. If iyou also need, contact us freely.

The features of potato chips production line:

1. The potato chips production line operation is simple, high degree of automation, no need for special operation, reduce labor costs.

2. The fully automatic potato chips production line has stable performance, long service life and low failure rate in the production process.

3. The production line saves oil and environmental protection, has high production efficiency, improves the market competition ability for the customer, has increased the profit space.

4. The potato chips production line is made of high quality stainless steel,safer and more hygienic production

5. The production line has large output and can be customized according to the needs of customers.

6. The thickness of potato chips can be adjusted or customized according to the special needs of customers.

Work flow of potato chips production line:

Lifting feed--washing and peeling--selection and pruning--lifting feed--cutting--blanching color protection--dehydration--frying--deoiling--seasoning--packaging.

Main machine of potato chips production line:

Washing and peeling machine:It can peel potatoes in a short time and has a low rate of breakage.The machine can be continuously peeled and cleaned.It saves water and no pollution than manual production.

Blanching machine:The machine is equipped with temperature control panel and heating timer.The machine needs to be filled with water.Turn on the switch and the water will heat up quickly.Place the potato chips in the machine and the machine begins to blanch.Blanching makes it easy to fry potatoes, saving more oil and electricity.Finished French fries or potato chips will also be beautiful in color and taste the best.

Dewatering machine:Before frying, remove the surface water from the hot stamped potato chips to save grease and avoid oil splashing.When the potato chips or french fries are put into the machine ,and turned on the machine, the machine will work at high speed and complete the dehydration process in a short time.

Frying machine:Made of food grade stainless steel.It consists of frying pan, electric heat pipe, control panel, motor and so on.Heating temperature and frying time can be adjusted according to your requirements.In addition, the machine adopts advanced technology to save oil and keep the taste and color of food.

Deoiling machine:Similar to the dehydrator, the machine is also made of food grade stainless steel.After frying, the finished fries or fries need to be de-oiled.This way, you won't get greasy eating chips or chips.Recycled oil can be reused to reduce production costs.

Seasoning machine:The roller mixing machine adopts the rotary drum, which is equipped with mixing plate to ensure the uniformity of the taste.

Precautions for use:

1. The machine should be placed in a stable place. The machine with wheels should lock the casters.

2. Please make sure that there is no foreign matter stuck in the material mouth of the machine. Please connect the power supply and ground wire according to the power supply instructions on the label.

3. Do not put your hands into the machine when the machine is in operation.

4. After using the machine, please be sure to cut off the power supply before cleaning the machine5. The circuit part cannot be cleaned. Please pay attention to sharp parts such as cutting tools when cleaning.

Technial Data

| No. | Name | Power | Dimension(mm) | Output(kg/h) |

| 1 | Potato Cleaner Peeler | 1.5kw | 1600*730*840 | 800 |

| 2 | Potato Cutting Machine | 1.1kw | 950*900*1000 | 700 |

| 3 | Blanching Machine | 24kw | 1000*500*800 | 500 |

| 4 | Centrifugal Dehydrator | 1.5kw | 1000*500*850 | 500 |

| 5 | French Fries Fryer | 36kw | 500*500*900 | 100 |

| 6 | Deoiling machine | 1.5kw | 1000*600*850 | 700 |

| 7 | Flavoring machine | 1.1kw | 1100*800*1300 |

600 |

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com