Features

The automatic potato chips producrion line is fully automatic processing chips from fresh potato to packed potato chips.As experienced potato chips production line manufacturers,we supply different capacity for customers,suh as 200 kg/h,300 kg/h,500 kg/h or more.The production line also can be used for processing french fries,forzen french fries,etc.It has the characteristics of high automation, high efficiency and energy saving.

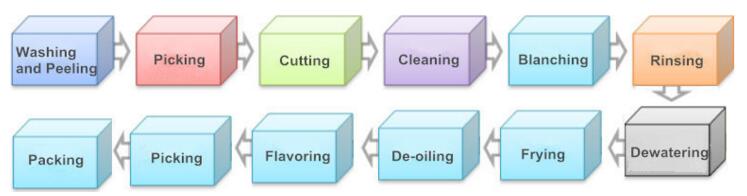

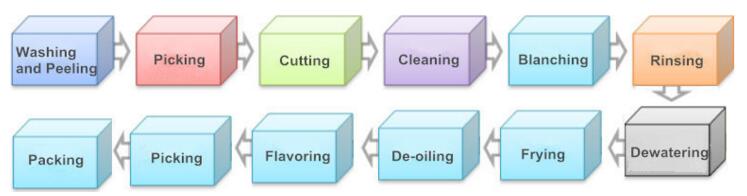

Potato Chips Manufacturing Process Flow Chart:

Working Machine In Potato Chips Processing Line:

Features of Potato Chips Processing Line:

Potato Chips Manufacturing Process Flow Chart:

Working Machine In Potato Chips Processing Line:

- Potato Washing and Peeling Machine:This machine integrates the function of washing and peeling, it can be used for processing potatoes, carrots, cassava and other root vegetables.

- Potato Chips Cutting Machine:This machine can cut the potatoes into slice or strips, just change different knives. The thickness of the chips or strips is adjustable.

- Blanching Machine:The machine has uniform heat transfer, controllable temperature and time.The main purpose of blanching is to ensure that potato chips are bright and crisp.

- Dewatering Machine: Dewatering is for the frying part.Dewated potato chips are low in water and easy to fry.Our potato chips dewatering machine adopts the centrifugal principle to remove water from the surface of potato chips through a rapidly rotating bucket.

- Potato Chips Frying Machine:it is adopted water-oil separating system. Thus it can extend the oil working life. This kind of fryer machine, it is continuous working, automatic feeding and automatic discharging, and the conveyor will take the material by conveyor to discharge.

- Deoiling Machine:Our potato chips deoiling machine adopts the centrifugal principle to remove oil from the surface of potato chips through a rapidly rotating bucket.

- Flavoring Machine:Customers can season diversified flavors totally according to their own intentions.

- Potato Chips Packing machine:This machine is used to pack the final product. Our fully automatic packing machine can feed, elevate, weigh and pack the potato chips automatically.

Features of Potato Chips Processing Line:

- Mature technology, easy operation, safe and reliable.

- Oil - water mixing technology is adopted in frying machine, the residue is easy to clean.

- This potato chips production line is automatic, thus it will saving labor to reduce the cost of operation the machines.

- All machines are made of Stainless Steel 304.

How does our Potato Chips Production Line work? This is we set potato chips line in Pakistan. If you also need, contact us freely.

Technial Data

| Item | Parameter |

| 1, Elevator |

0.75kw/380v/50Hz 2000*800*2000mm |

| 2, Cleaning and Peeling Machine |

4.75kw/380v/50Hz 1800*900*1500mm |

| 3, Sorting Conveyor |

0.75kw/380v/50Hz 3000*900*900mm |

| 4, Potato Chips Cutting Machine |

1.5kw/380v/50Hz 950*800*950mm |

| 5, Rinshing Machine |

5kw/380v/50Hz 3500*1600*900mm |

| 6, Blanching Machine |

70kw/380v/50Hz 3500*1600*950mm |

| 7,Vibrating and Water Removing Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| 8,Sorting Conveyor |

0.75kw/ 380V/50Hz 4000*800*1000mm |

| 9, Air Cooling and water removing machine |

15kw/380v/50Hz 4000*1200*1400mm |

| 10,Elevator |

0.75kw/380v/50hz 2500*800*1300mm |

| 11, Electric Continuous Fryer Machine |

120kw/380v/50Hz 4000*1200*2600mm |

| 12, Vibrating and Oil Removing Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| 13,Air Drying Machine |

8kw/380v/50Hz 4000*1200*1600mm |

| 14,Elevator |

0.75kw/380v/50Hz 2400*800*2200mm |

| 15,Flavoring Machine |

50kw/380v/50hz 2500*900*1500mm |

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com