What Is The Production Line for Potato Chips?

Jan 08, 2024 | Emily

186

186

186

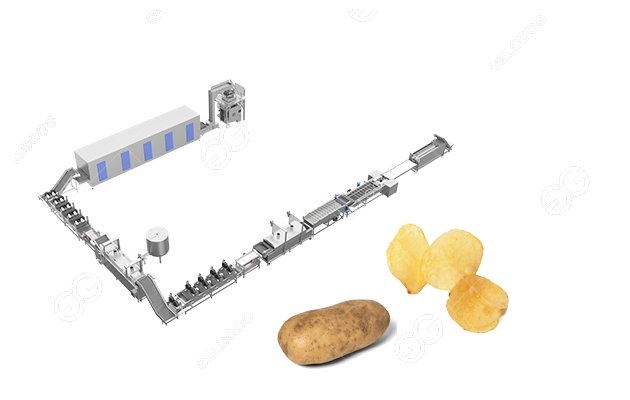

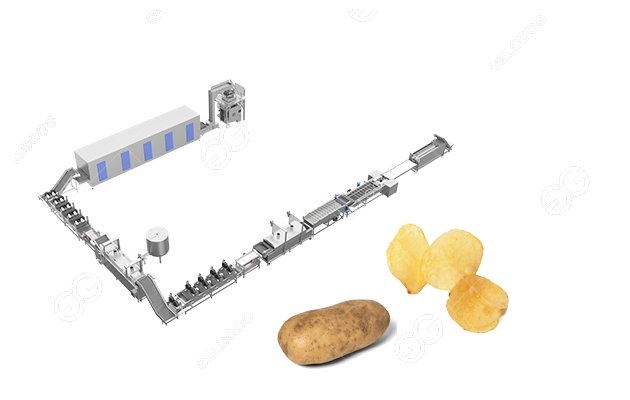

186

Potato chips, those crispy and flavorful snacks loved by people worldwide, undergo a fascinating journey from humble potatoes to the enticing bags that line store shelves. The production process of potato chips in a factory is a well-orchestrated dance of machinery, precision, and quality control. In this article, we will take a detailed look at the production line for potato chips in a factory, exploring the key stages that transform raw potatoes into the beloved snack we all know.

Raw material handling:

The process begins with the careful selection and handling of raw potatoes. High-quality potatoes are chosen to ensure a consistent taste and texture. Potatoes are thoroughly cleaned and inspected to remove any impurities. The choice of potato variety can also influence the final flavor and texture of the chips.

Peeling and slicing:

After the initial inspection, the potatoes are peeled to remove the skin. This step is crucial to achieve a uniform appearance in the final product. Once peeled, the potatoes are sliced into thin, even slices. Advanced slicing machinery ensures precision and consistency in thickness, a critical factor for the desired crispiness of the chips.

Washing and blanching:

The sliced potatoes undergo a thorough washing process to remove excess starch. Subsequently, they are blanched in hot water or steam. Blanching serves multiple purposes, including the partial cooking of the potatoes, setting the desired color, and preparing them for the next stage of the process.

Drying:

The blanched potato slices are then dried to remove excess moisture. Proper drying is essential for achieving the characteristic crunchiness of potato chips. Industrial dryers, often utilizing hot air, remove moisture while maintaining the integrity of the potato slices.

Frying:

One of the most iconic stages of potato chip production is the frying process. The dried potato slices are immersed in hot oil, typically vegetable oil, until they reach the desired level of crispiness and golden color. Continuous fryers ensure a consistent product by carefully controlling temperature and cooking time.

Seasoning:

Once the chips have been fried to perfection, they are ready for seasoning. Seasoning is a critical step in creating the diverse range of flavors that potato chips offer. Whether it's classic salt, barbecue, sour cream and onion, or innovative flavors, the seasoning is applied evenly through a carefully calibrated process.

Quality control:

At every stage of the production line, rigorous quality control measures are in place. Automated systems and skilled personnel inspect the chips for color, texture, flavor, and overall quality. Any substandard chips are removed from the production line to maintain a consistent standard.

Packaging:

The final step involves packaging the potato chips into the familiar bags that consumers recognize. Automated packaging machines weigh and fill the bags with the appropriate quantity of chips. The bags are then sealed, often with nitrogen flushing to maintain freshness, and labeled for distribution.

The production line for potato chips is a marvel of engineering and precision. From the careful selection of raw materials to the final packaging, each stage plays a crucial role in delivering the delightful snack we enjoy. The blend of technology, craftsmanship, and quality control ensures that every bag of potato chips meets the high standards set by both manufacturers and consumers alike. The potato chip production line is a testament to the innovation and efficiency that drive the modern food industry.

Raw material handling:

The process begins with the careful selection and handling of raw potatoes. High-quality potatoes are chosen to ensure a consistent taste and texture. Potatoes are thoroughly cleaned and inspected to remove any impurities. The choice of potato variety can also influence the final flavor and texture of the chips.

Peeling and slicing:

After the initial inspection, the potatoes are peeled to remove the skin. This step is crucial to achieve a uniform appearance in the final product. Once peeled, the potatoes are sliced into thin, even slices. Advanced slicing machinery ensures precision and consistency in thickness, a critical factor for the desired crispiness of the chips.

Washing and blanching:

The sliced potatoes undergo a thorough washing process to remove excess starch. Subsequently, they are blanched in hot water or steam. Blanching serves multiple purposes, including the partial cooking of the potatoes, setting the desired color, and preparing them for the next stage of the process.

Drying:

The blanched potato slices are then dried to remove excess moisture. Proper drying is essential for achieving the characteristic crunchiness of potato chips. Industrial dryers, often utilizing hot air, remove moisture while maintaining the integrity of the potato slices.

Frying:

One of the most iconic stages of potato chip production is the frying process. The dried potato slices are immersed in hot oil, typically vegetable oil, until they reach the desired level of crispiness and golden color. Continuous fryers ensure a consistent product by carefully controlling temperature and cooking time.

Seasoning:

Once the chips have been fried to perfection, they are ready for seasoning. Seasoning is a critical step in creating the diverse range of flavors that potato chips offer. Whether it's classic salt, barbecue, sour cream and onion, or innovative flavors, the seasoning is applied evenly through a carefully calibrated process.

Quality control:

At every stage of the production line, rigorous quality control measures are in place. Automated systems and skilled personnel inspect the chips for color, texture, flavor, and overall quality. Any substandard chips are removed from the production line to maintain a consistent standard.

Packaging:

The final step involves packaging the potato chips into the familiar bags that consumers recognize. Automated packaging machines weigh and fill the bags with the appropriate quantity of chips. The bags are then sealed, often with nitrogen flushing to maintain freshness, and labeled for distribution.

The production line for potato chips is a marvel of engineering and precision. From the careful selection of raw materials to the final packaging, each stage plays a crucial role in delivering the delightful snack we enjoy. The blend of technology, craftsmanship, and quality control ensures that every bag of potato chips meets the high standards set by both manufacturers and consumers alike. The potato chip production line is a testament to the innovation and efficiency that drive the modern food industry.

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com